Our Product

1. With 1000-6000mm effective lifting stroke and retracting stroke.

2. Boom end capacity up to 300kg. With 100x100mm cross slides.

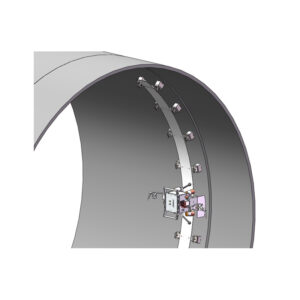

3. Automatic welding for tank/pipe/vessel straight seam and circle seam.

4. Seam tracker and Monitor to make sure the welding result better.

5. Flux recovery machine is also can be optional.

6. Voltage 220V 380V 480V 600V 50/60Hz are all can be customized

7. Remote hand control box is also standard configuration

8. Working with welding rotator and welding positioner etc

9. Welding source can be Tig/Mig/Saw welding,even plasma welding source

10. Outside seam welding,inside seam welding and circle seam welding.

2. Boom end capacity up to 300kg. With 100x100mm cross slides.

3. Automatic welding for tank/pipe/vessel straight seam and circle seam.

4. Seam tracker and Monitor to make sure the welding result better.

5. Flux recovery machine is also can be optional.

6. Voltage 220V 380V 480V 600V 50/60Hz are all can be customized

7. Remote hand control box is also standard configuration

8. Working with welding rotator and welding positioner etc

9. Welding source can be Tig/Mig/Saw welding,even plasma welding source

10. Outside seam welding,inside seam welding and circle seam welding.

Groove welding process

1. Automatic welding, bottoming, filling and capping are integrated, there is a gap

between the counterparts, and gaskets are needed: ceramic or steel gaskets on the back; no gaps and gaskets are needed for the counterparts: a layer is welded after the back is cleaned: DPS-500A+A-300N

Welding wire: 1.2mm gas shielded solid core welding wire with bottom filling and covering surface, high efficiency and low cost.

Gas: 70%CO2+ 30%Ar

Process characteristics: simple equipment configuration, high welding efficiency, 3 times that of traditional welding rods

Groove processing requirements: relatively standardized

Suitable working conditions: automatic welding of lower pressure pipelines such as water pipelines and municipal