| Comparision between MIG and SAW welding for LPG gas cylinder | ||

| 2000 pcs cylinders/8 Hours | ||

| Description | MIG welding | Saw welding |

| Capacity | 360 pcs/8hrs/set | 240 pcs/8hrs/set |

| No. of welding machines | 6 | 8 |

| No. of welders | 3 | 39 |

| No of welding pass | one path | two paths |

| Power consumption | MIG saves 40% than SAW | |

| Wire consumption | MIG saves 40% than SAW | |

| Auto laser & video tracing device | MIG welder has auto laser & video tracing device, SAW welder does not | |

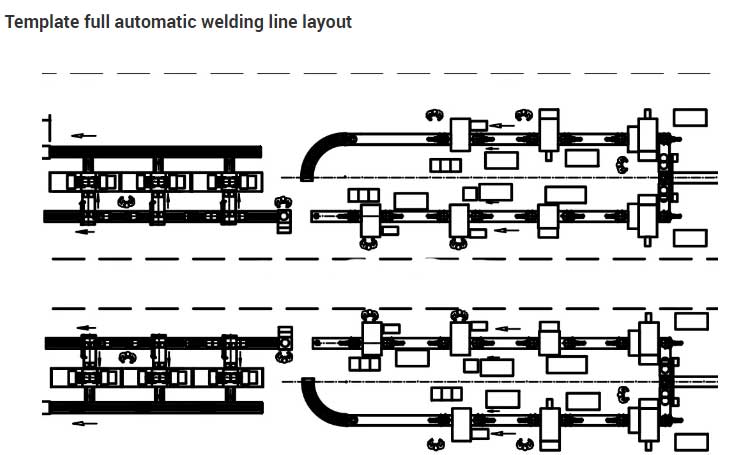

Full-auto welding machine includes socket welding, handle/collar welding, base ring welding, circumference welding, and all machines work automatically, the cylinder halves are conveyed by mechancial arm and chain, this system really saves much labor cost and improve the working efficiency apparently.

Full auto socket welding

This machine is used for upper cap socket welding and edge welding part polishing. Equip with Panasonic YD-350GL4 welder 1 set, water cooling welding torch 1 pcs, 8L automatic cycle water cooling tank 1 set. The main shaft motor is 0.75KW. Polishing motor is 1.5KW, equip with the grating security protection.

Equip with NO. 6 Hydraulic station, 1 set, vane pump, 5.5KW. Setting pressure: falling 4 MPa, rising 9 MPa.

Full auto handle welding

This machine is used for upper cap hadnle welding. Equip with three sets welding torch, 3 welders finish at one time. Equip with

Panasonic YD-350GL4 welders 3 sets, welding torch 3 pieces. Main shaft motor is 0.4KW, with the grating security protection.Equip with No.7 hydraulic station, vane pump, 5.5KW. Setting pressure: pressing 4MPa, rising 9MPa.

Panasonic YD-350GL4 welders 3 sets, welding torch 3 pieces. Main shaft motor is 0.4KW, with the grating security protection.Equip with No.7 hydraulic station, vane pump, 5.5KW. Setting pressure: pressing 4MPa, rising 9MPa.

Full auto base ring welding

This machine is used for lower cap bottom base welding, equip with three welding torch, 6 welders could be finished at two times. Equip

with Panasonic YD-350GL4 welder 3 sets, welding torch 3 piece. Main shaft motor 0.4KW, with the grating security protection. Equip with No.3 hydraulic station, vane pump, 5.5KW, setting pressure: pressing 4MPa, rising 10MPa.

with Panasonic YD-350GL4 welder 3 sets, welding torch 3 piece. Main shaft motor 0.4KW, with the grating security protection. Equip with No.3 hydraulic station, vane pump, 5.5KW, setting pressure: pressing 4MPa, rising 10MPa.

Full auto single head circumference welding

This machine is used for cylinder upper shell and lower shell welding, it adopts seam

vision tracking device, automatic imaging to tracking welding seam, welding the circumferential seam automatically, no need of manual intervention. It adopts Panasonic 500GS (special) high-speed pulse MIG welding source. Welding speed can reach to

1000mm/min. It adopts double internal cooling MIG torch, it is suitable for long time welding. It is equipped with Supercooler

automatic circulating cooling water tank to cooling the welding torch circularly.

vision tracking device, automatic imaging to tracking welding seam, welding the circumferential seam automatically, no need of manual intervention. It adopts Panasonic 500GS (special) high-speed pulse MIG welding source. Welding speed can reach to

1000mm/min. It adopts double internal cooling MIG torch, it is suitable for long time welding. It is equipped with Supercooler

automatic circulating cooling water tank to cooling the welding torch circularly.