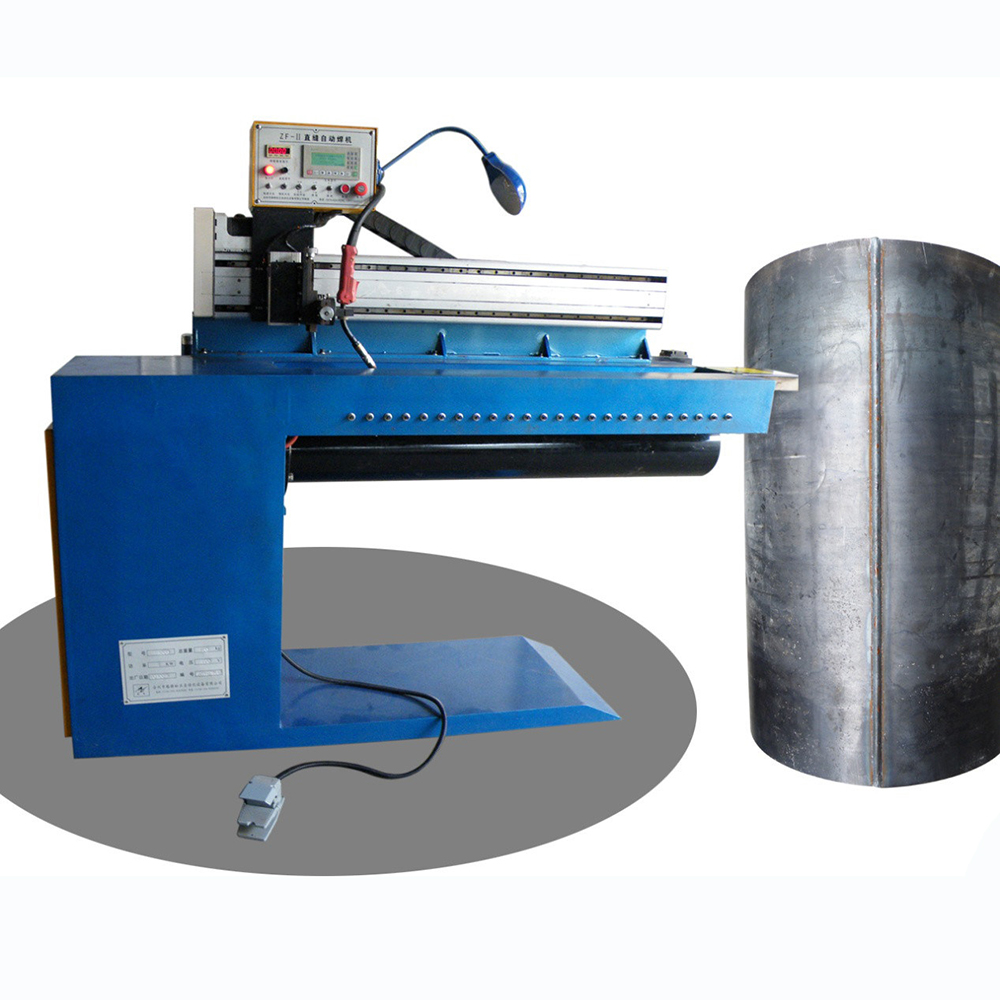

Welding is used for permanent bonding of metal or plastic materials. It is commonly used in metal or thermoplastic materials. In this method, the component to be connected is melted and then filler material is added to the component. Then, cool and solidify. In some cases, welding can be completed under pressure. There are many different welding methods in the production field. The fire extinguisher welding line is used to connect the production pipe body.

Welding wires are used to connect the ends of curved plates and connect parts together. This production line is very important in production because the welding to prevent leakage of fire extinguishing materials must be very smooth. Equally important, these resources are based on a specific level of stress. If the welding machine does not produce the correct results, the cylinder will not be used.

The fire extinguisher is produced in three pieces in a roll to roll manner; The main body is bent from a plate, and the head and bottom cover are made by a deep drawing method. Depending on whether the cylinder is formed by deep drawing, there can be two welding stages.

| No. | Item | Main parameter(mm) |

| 1 | Max diameter of workpiece welding | 500 |

| 2 | Min diameter of workpiece welding | 90 |

| 3 | Max length of workpiece welding | 600 |

| 4 | Max thickness of workpiece;Min thickness of workpiece. | <= 2.5 >=0.6 |

| 5 | Rated input voltage | AC220V two phase |

| 6 | Frequency | 50HZ |

| 7 | Rated Input Capacity | 1KW |

| NO. | Item | Main parameter(mm) |

| 1 | Max welding diameter | Φ200 |

| 2 | Min welding diameter | Φ90 |

| 3 | Max welding length | 600 |

| 4 | Welding | 350A |

| 5 | Rated input voltage | AC220V Two phase |

| 6 | Frequency | 50HZ |

| 7 | Rated Input Capacity | 1KW |